- HOME

- Nagakura Spirits

Nagakura Spirits

Impact to the NextWe are an enabling company

Nagakura has always achieved products that are said to be impossible.

It may be impossible today, but tomorrow we will achieve.

“It is impossible with Nagakura’s capacity,” “You cannot process with using cold forging,”

“cannot entrust in you,” “Cannot entrust this project with the Japanese,”

“impossible,” and “cannot do,” are all quotes used as motivation to achieve.

We will impact the future by everyday training because there is no limit to technology and effort.

With trained technology, we achieved overseas development and realization in trading and trusting with many makers.

1950 — 1990

Introduction to Cold Forging Technology

Nagakura started as a screw bolt manufacturing company during the post war era.

Since then we came to support the automotive industry by switching from screw bolt to manufacturing automobile parts due to the economic development of Japan.

1990 — 2020

Nagakura forcus on global market

With the beginning of the Japan-U.S. trade friction during the first half of the 1990s, many of the suppliers were advancing with overseas expansions of the domestic car makers.

As we expanded our customer base in Indiana and Vietnam, in 2014 we established in Mexico with a vision of maximizing a manufacturing base for NAFTA area. We have developed a quick delivery system to our customers in the North American continent.

2020 —

“As a world leading cold forging company…”

As a world leader in cold forging, we are seeking Research and Development for more advanced forging technology in order to contribute to society, and having a large impact on the world with cheaper, faster and higher quality parts. It is a proposition of Nagakura for the year 2020.

VisionVision of Nagakura Manufacturing

After the war, the manufacture of screws in the Japanese industry was very useful. After that, on the background of high economic growth, we would advance to parts for motorcycles and automobiles due to the change in the market.

In particular, the evolution of the past 20 years has been remarkable, we have been able to predict accelerated technological innovation and lifestyle transformation.

In the future, 30 years from now, we do not know the necessity of the industry, but there is always something that only "iron specialists" can do. This is based on the forging technology that has a history dating back to the HEIAN Period.

We will continue to deliver the quality of "Made in JAPAN" to markets all over the world.

We will aim to be the company still useful and needed in the world.

Project Story VOL.01

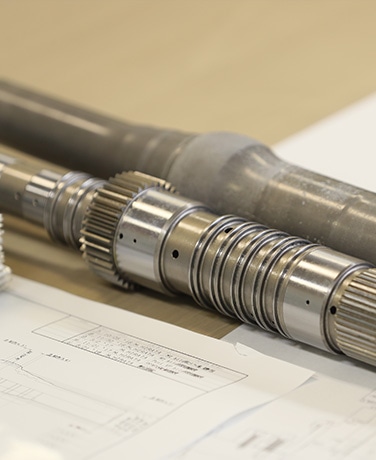

The challenge of producing the world’s longest cold forged parts (700 mm shafts).

Nagakura Manufacturing Co., Ltd. is a company that can respond to the world's market of cold forging.

We take pride in the production of our unparalleled world longest parts.

Project Story VOL.02

Product development support of the new generation transmissions of ZF Company.

Presently, the Nagakura Production Office deals with many overseas clients.

This was triggered by the project development and manufacturing of the 9 speed transmission proposed by ZF company in Germany.We have built a trend with the development of the improvement of high energy efficiency multi-shift transmission.

Project Story VOL.03

Construction of new base in North American market, “Mexico Plant”

To go forth with the automotive industry in the North American market and along with the factory in Indiana, we have constructed a project in Mexico.